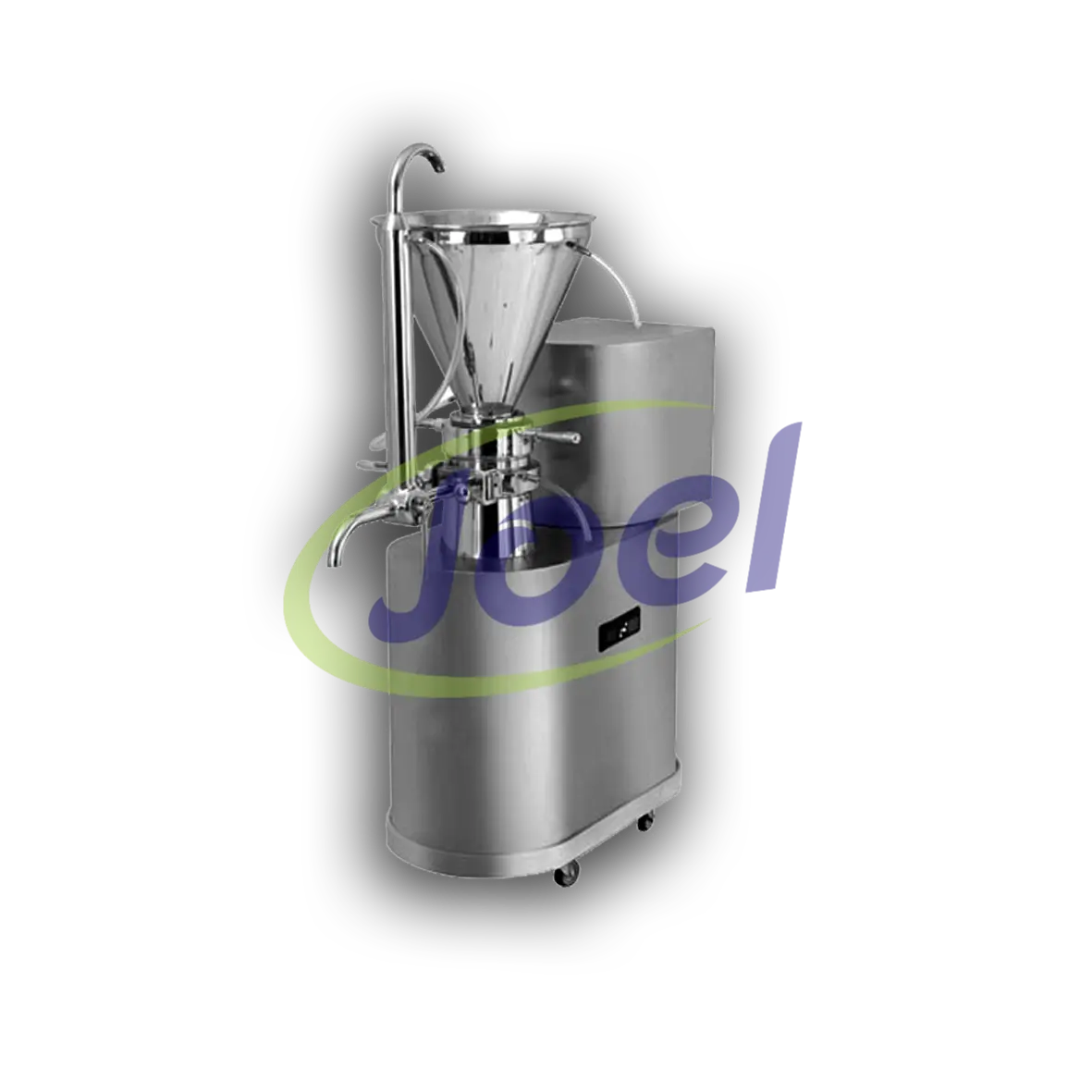

Colloid Mill is suitable for homogenizing emulsifying dispersing, mixing, comminuting of liquids to highly viscous products up to 5 to 10 micron particle size. It is also used for further grinding of sediments and fibre contents in the medicines to form a clear liquid. High shear, cutting, and friction forces are applied to the product when it is delivered into the cutting chamber. The angular gap gets less as it approaches the outlet portion due to the somewhat differing adhesive side of the stator and rotor’s milling surfaces. The material that has been processed constantly exits the mill by the drainpipe; if necessary, it is circulated repeatedly.